19 Aug Conformity Assessment Under EU 2023/1542: Why It’s Not Just a Formality

Conformity Assessment Under EU 2023/1542: Why It’s Not Just a Formality

19 August 2025

By Valentina D’Amelio, PhD – Innovations Manager, NMi Certin

With the EU Battery Regulation (EU 2023/1542) now in force, the topic of conformity assessment is gaining much-needed attention. Yet, in many of my conversations with battery manufacturers and OEMs, there’s still uncertainty about what this process really entails, and more importantly—when to engage with it.

Let me be clear: this isn’t just a regulatory formality. Conformity assessment is the legal, technical, and strategic backbone of your product’s entry into the EU market. And in practice, getting it right is often more complex than many businesses initially expect.

What Conformity Assessment Actually Means

At its core, conformity assessment is the structured process that confirms a battery complies with the requirements of the EU Battery Regulation—and earns the CE marking as a result. That CE mark isn’t optional; it’s what gives a battery legal access to the EU market.

What’s often overlooked is that conformity assessment is not just a one-time check. Depending on the battery type, production scale, and applicable articles of the regulation, the process may involve internal procedures, third-party oversight, or both.

You’re Likely Responsible—Even If You Didn’t Build the Battery

A recurring point of confusion is responsibility. Under the Regulation, the “producer” is the entity that places the battery on the EU market. That means if you’re importing batteries, integrating them into a system, or branding them as your own, the responsibility to ensure conformity—and apply the CE mark—may fall to you.

And that responsibility comes with several concrete obligations:

- Mapping which articles of the regulation apply,

- Choosing the correct conformity assessment module,

- Preparing technical documentation,

- Engaging a Notified Body if required,

- Ensuring continued compliance post-placement.

There’s value in starting early. Achieving full compliance under the Battery Regulation requires coordination across multiple functions—engineering, sustainability, regulatory, and supply chain. It takes time to align suppliers, implement quality systems, engage with a Notified Body if needed, and compile the necessary technical documentation. With several requirements phasing in over the coming years, a forward-looking approach allows you to plan effectively, avoid last-minute complications, and maintain control over both timelines and costs.

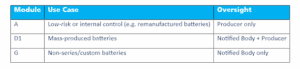

Choosing the Right Module: It’s Not Always Obvious

There’s no one-size-fits-all route for conformity assessment. The Regulation defines different “modules,” each with a distinct set of responsibilities and oversight levels:

For sustainability-related obligations (e.g. carbon footprint or recycled content), a Notified Body is always required, regardless of production volume.

Here’s where misunderstandings frequently happen. For example, a company producing small batches of specialized industrial batteries may assume they fall under D1—but without a formal quality system, such as ISO 9001 in place, that route isn’t available. In those cases, Module G applies instead, which means each battery must undergo individual verification by a Notified Body. That represents a significantly different level of effort, oversight, and cost.

The Risks of Getting It Wrong

While the goal of the EU Battery Regulation is to raise industry standards—not to catch companies out—non-compliance can lead to real business challenges, especially if key requirements are misunderstood or addressed too late in the development cycle.

In our work with battery producers and OEMs, we see issues often arise from grey areas, such as how conformity assessment modules apply to different battery types, or which documentation is sufficient for new sustainability disclosures. Some common pitfalls include:

- Uncertainty around the appropriate assessment route,

- Gaps or inconsistencies in technical documentation,

- Incomplete or unsupported carbon footprint declarations,

- Missing Notified Body involvement where it’s explicitly required.

These aren’t necessarily regulatory violations on their own—but they can slow down approvals, create uncertainty at customs, or result in additional audits and clarifications once products are already in the market.

In parallel, the Regulation introduces due diligence obligations for producers with annual turnover above €150 million. These obligations relate to human rights and environmental risk management in the raw materials supply chain—and they are auditable. Without a clear process in place, companies may face questions not only from regulators, but also from customers, partners, and investors who increasingly expect robust ESG governance.

In Practice: What You Should Be Doing Now

From a practical standpoint, I advise companies to take the following steps:

- Identify the battery category. Determine whether your product is a portable, industrial, EV, or LMT battery. This defines which parts of the regulation apply.

- Map each article of the regulation. Review Articles 6–14 (performance, safety, labelling), Articles 7–8 (carbon footprint and recycled content), and Articles 47–50 (due diligence). Understand how these apply to each battery type and market application.

- Determine the correct conformity assessment module. Based on your production method and applicable obligations, select the appropriate module (A, D1, or G), and document your rationale.

- Engage with a future Notified Body early. This is particularly important for batteries requiring carbon footprint declarations, recycled content disclosures, or supply chain due diligence. In many of these cases, Notified Body involvement is mandatory.

- Ensure your technical documentation is complete and consistent. This includes conformity declarations, labelling records, audit trails for sustainability claims, and test results. Consistency across teams (engineering, legal, ESG, and regulatory) is key.

- Establish internal alignment. Make sure everyone involved understands the shared responsibilities. Clarify which team or stakeholder owns what portion of compliance, especially when external suppliers or integrators are involved.

📌 An example I often refer to: A client integrating third-party battery packs into their industrial systems assumed the supplier’s CE mark was sufficient. Upon deeper review, we found the packs weren’t assessed under the correct module for EU use, and no documentation was available for Article 8 recycled content claims. Early review helped resolve it, but it required redesigning part of the documentation flow and adding supplier controls.

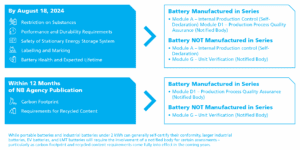

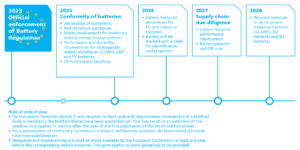

Key EU Battery Regulation Compliance Milestones

Compliance isn’t just about what’s required—it’s also about when. Several critical deadlines are fast approaching, particularly for sustainability and due diligence obligations. Here’s a high-level view of the timeline we help clients plan against:

A Note on Timing: Capacity Will Become a Bottleneck

One important point to highlight is that there is no time to lose. When the first wave of enforcement begins, Notified Bodies across Europe—including NMi—will be under pressure to handle a sharp rise in assessment requests. Engaging now means you’re securing your certificate tomorrow—not risking a delay the day after.

We are already seeing a high volume of inquiries, particularly around carbon footprint, Module D1, and due diligence obligations. Starting your assessment process early helps reduce the risk of project delays, gives you more flexibility in planning, and ultimately keeps costs under control. The closer we get to enforcement deadlines, the more constrained those options will become.

Where NMi Certin Supports

As a Notified Body with experience across regulated testing, inspection and certification, NMi supports battery producers and OEMs throughout the conformity journey:

- Reviewing and verifying CE documentation

- Auditing quality systems under Module D1

- Conducting unit verification for Module G

- Assessing carbon footprint and recycled content declarations

- Evaluating due diligence frameworks for supply chain compliance

Beyond verification—we also provide standardised trainings for Module D1, carbon footprint declarations, and due diligence under the EU Battery Regulation to help your teams build internal capability and stay ahead of upcoming requirements.

Final Thought: Treat Conformity Like a Design Input

Too often, conformity assessment is treated as something to “figure out later.” But just like thermal stability or charge cycles, it should be a core part of your battery’s design and production strategy.

The sooner you address it, the more options you have—and the fewer surprises you’ll face when bringing your products to market. If you’re unsure about which module applies to your batteries—or how to structure your documentation—let’s talk.

Reach out to Valentina D’Amelio or contact nmi@nmi.nl to start a conversation.